We are Distributor of Products made in Germany

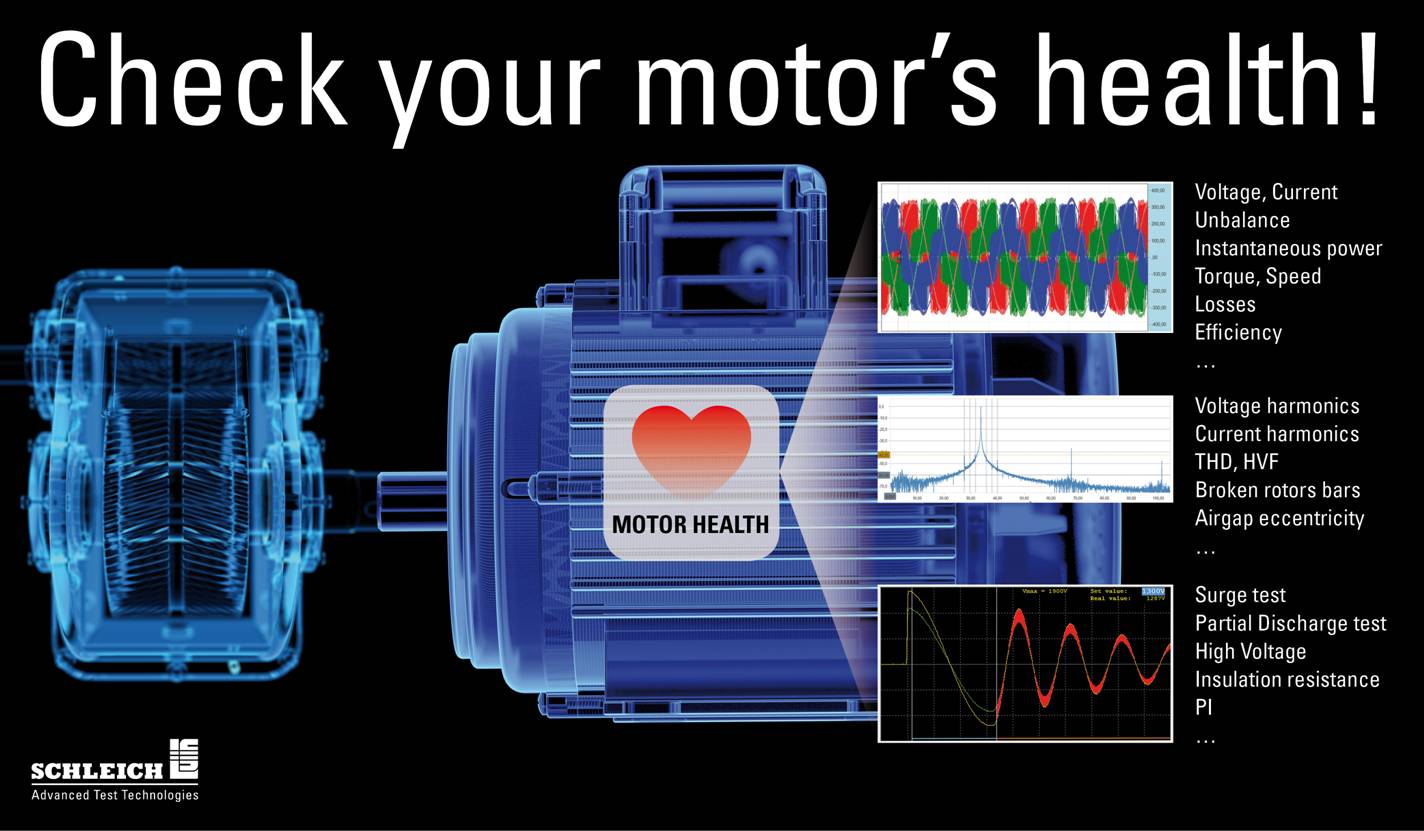

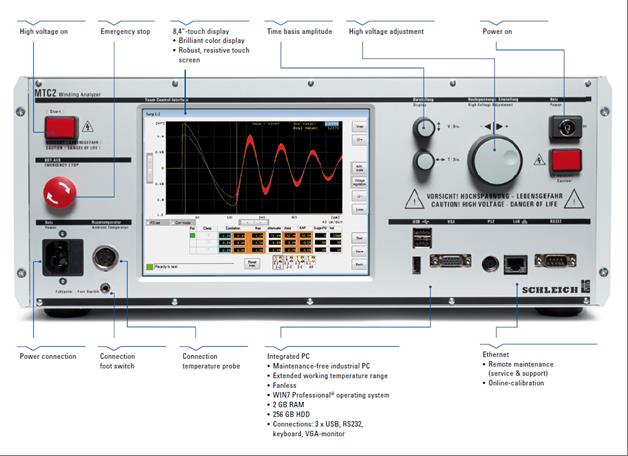

The all-purpose MotorAnalyzer 2 is used for checking electric motors and windings.

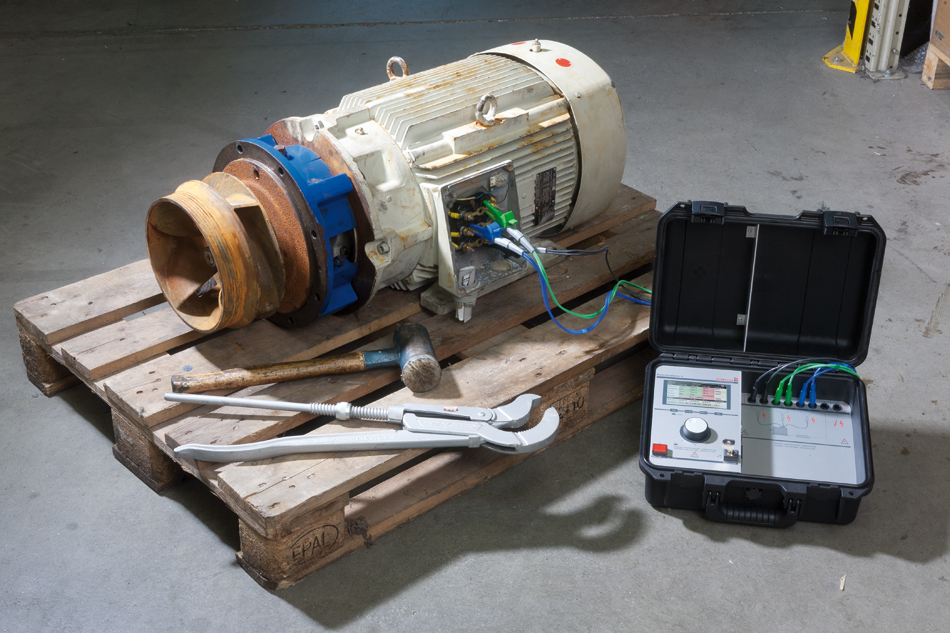

It combines 13 different test methods within a user-friendly and mobile tester. The combination of test methods, its compact design, as well as the battery operation, turn the MotorAnalyzer 2 into an ideal tool for on-site operation, especially in difficult applications.

For checking a 3-phase motor the three winding connections and the motor’s frame are connected to the tester.

This testing is done with four wire technology, providing high precision resistance measure-ments. After the Kelvin resistance test, the MotorAnalyzer 2 performs fully automatic testing via surge test, resistance and inductance.

The MotorAnalyzer 2 automatically switches between different tests via its internal relay matrix. Finally, a high voltage test is done to evaluate the motors quality.

In addition, the MotorAnalyzer 2 provides information on brush holders and turn-to-turn faults within DC motors.